Hydroponic systems: Everything you want to know about Greenhouse hydroponics & hydroponics growing system

With the right resources, it is not hard to understand hydroponic systems. On this comprehensive page about hydroponic systems, you will read and learn about the principles behind hydroponics, how an indoor hydroponic system works and how to use greenhouse hydroponics to produce high-quality crops.

We will also address many frequently asked questions about hydroponics, such as how plants can be grown without soil, which growing substrate you should use for your hydroponic plants, the benefits of hydroponics, the challenges of hydroponics, and whether tomatoes taste different when compared to soil-grown field tomatoes.

Table of contents:

- Table of contents:

- What Is Hydroponics? – Introduction to Hydroponics

- 2024 Market Potential of hydroponics

- History of the Hydroponic Grow System:

- How Does Growing Plants In Water Work?

- Hydroponic substrates / Hydroponic grow medium

- What Can You Grow Hydroponically?

- 5 Benefits Of Hydroponics:

- Suitable hydroponically grown crops

- 4 Challenges Of Hydroponics:

- Reverse osmosis commercial systems in greenhouses

- Propagation Plants in a Hydroponic System:

- Commercial Hydroponics System:

- 6 Types of hydroponics growing systems

- What is the most profitable plant to grow hydroponically in a greenhouse? And why?

- How hard is hydroponic growing?

- FAQ about greenhouse hydroponics

What Is Hydroponics? – Introduction to Hydroponics

-

Hydroponics can be defined as a modern agriculture technique to grow plants in a nutrient solution rather than soil. It is a soil-less crop production method.

In agriculture, soil is the most widely used and available medium for growing crops for food production.

The term “medium” refers to the material or substance in which plants develop their roots. Soil provides plants with essential nutrients, water, and air to ensure effective growth.

However, in this soil medium, there are also many plant-harming microorganisms such as insects, fungi, and plant diseases (viruses) that can limit the potential growth of plants.

To grow a large quantity of high-quality crops that can be sold at a higher price, a ‘clean’ starting environment (medium) without diseases and insects is important.

Unlike traditional soil-based cultivation, hydroponics utilizes a soilless growing environment.

The medium in hydroponics provides support to the plant roots and facilitates the direct delivery of water, nutrients, and oxygen to the root system.

2024 Market Potential of hydroponics

-

The hydroponic growing system is most widely used in European greenhouses, with the Netherlands, Spain, and France being the top producers of crops in hydroponic systems. The USA and the Asia-Pacific region follow closely behind them.

This hydroponic system presents numerous advantages, such as enhanced yields, a shorter crop cycle (meaning that crops grow faster), and easier control and adjustment of the root zone growing environment (including pH and EC levels).

Because of this, using hydroponics is becoming more favorable for farmers growing vegetables, flowers, and soft fruits worldwide.

To utilize a hydroponic growing system and produce crops commercially, a controlled environment such as a greenhouse is essential.

According to a recent market analysis (2022), the hydroponic market was valued at USD 35.2 billion in 2022.

With a Compound Annual Growth Rate (CAGR) of 7.5% projected between 2023 and 2030, the market is expected to reach a value of USD 58.3 billion by 2030.

This growth can be explained by, among other factors, the adaptability of hydroponics, enabling crop cultivation anywhere without reliance on local soil conditions, but rather on a nutrient mixture.

With more degraded soil worldwide and motivated governments encouraging local food production in their own countries (even in climates traditionally unsuitable for crop production), hydroponics systems and greenhouses are more being installed.

Additionally, the increasing consumer preference for cleaner, pesticide-free produce, combined with the wish for higher production yields, contributes to the growth of the hydroponic market.

Hydroponics allows for the cultivation of crops without the application of any chemicals, offering a healthier and more environmentally friendly option by reducing pesticide usage.

Consumer awareness of this often applies to crops that are eaten raw, such as leafy greens and edible flowers.

History of the Hydroponic Grow System:

The development of Modern Hydroponic Systems

About 100 years ago (in 1929 to be precise) William Frederick Gericke (1882-1970) was researching a plant-growing system that we know today as hydroponic.

William Frederick Gericke worked at the University of California and was one of the first to experiment with hydroponic growing.

The word “hydroponic” is derived from the Ancient Greek word γεωπονικά (pronounced geoponika), which literally means “of agriculture” or “for agriculture.” The Greek word γαία (earth) was replaced by ὑδρο (hydro) = water, and together they form the word υδρωπονικά (pronounced hydroponika).

The second part of the word relates to ‘labor’. William Frederick Gericke was also the one who introduced the word of hydroponic in 1937.

Later, in 1946, the English scientist W.J. Shalto Douglas introduced the hydroponic system in West Bengal, India.

Starting around 1960-1970, commercial hydroponic farms were established in many countries globally.

Very often, crops grown in a controlled environment agriculture system are those that can be sold for a higher market price (cash crops) or crops that need to appear as “clean.”

Some examples of greenhouse horticulture crops include:

- Lettuce

- Tomatoes

- Bell pepper

- Strawberries

- Medicinal Cannabis

Some other major products of controlled environment agriculture, of which many consumers are not aware, include mushrooms, insects (for protein production), and fish (aquaponics).

Early Hydroponic Systems: Aztec Floating Garden of 9000 ha in Mexico

The greenhouse hydroponics that we know today can be traced back to the Aztec civilization (1345 AD and 1521 AD). The Aztecs, present in central Mexico, were already building floating structures with crops using the same principles as modern hydroponics.

Aztec agriculture was ahead of other civilizations in the world at the time.

Aztech agriculture in Tenochtitlan with floating gardens - The history of Chinampas aztecs

Tenochtitlan, the city-state where the Aztecs lived, was an island, making it difficult to obtain new agricultural land.

They discovered and implemented an efficient hydro grow system that formed the floating gardens in Mexico City.

This system was so efficient that the Aztecs were able to feed their population of 11 million people.

The hydro grow system consists of chinampas. A chinampa is a floating reed plate on water with dimensions of approximately 50 cm x 150 cm. The Aztecs could grow crops efficiently on this. By growing on water, irrigating the crops was no longer a problem.

This allowed them to harvest crops up to four times a year. The covered area with these Chinampas is estimated to be 9000-10000 ha! The fishes in the canals enriched the soil with nutrients of the feces.

How Does Growing Plants In Water Work?

The Principles Behind Hydroponics

When growing plants in water with hydroponics, the plants grow in a nutrient solution, with their roots partly immersed in the solution.

All the macro and micro nutrients, which are also found in soil, are present in this nutrient solution.

This means that in a hydroponic setting, there is no need for soil at all, which plants normally use to extract nutrients through their roots.

Please note that this nutrient solution is not just tap water; it consists of water mixed with a specially made liquid nutrient in a predetermined ratio.

The nutrients required by plants are directly given to them in a hydroponic environment.

The plants get what they need in the right proportion and at the right time, resulting in more efficient nutrient uptake.

Hydroponic growing and hydroponic roots development

Hydroponic roots are different

In comparison to the roots of crops growing in soil, hydroponic roots are significantly shorter and thinner, often less extensively developed.

This is advantageous for the plants because less energy is then spent on root development, allowing more energy to be allocated to the growth of leaves and fruit.

The key reason behind why the hydroponic roots are different, is that the roots are consistently surrounded by water with constant feeding of nutrients to the roots, eliminating the need for the plant roots to “search” for water and nutrients.

Hydroponic substrates / Hydroponic grow medium

While hydroponics reduces the need for soil, a growing medium or substrate is still used to support plant roots and provide stability for the plants in a commercial hydroponic greenhouse.

Common hydroponic substrates (hydroponic grow media) include hydroponic rockwool, hydroponic coconut coir and hydroponic perlite.

-

Rockwool is one of the hydroponic growing mediums for plants. Choosing the right grow medium is important.

Hydroponic rockwool

Often, people ask what is rockwool made out of? Rockwool is obtained from the volcanic rock basalt or diabase. By heating this rock vigorously and swirling it around, threads are formed. Through further processing, mats of rockwool are eventually created.

A crucial difference between rockwool for insulation and growing substrate is that rockwool used for insulation in construction is water-repellent, while rockwool used for growing crops absorbs water.

The ability to absorb water is important, as it keeps the plant roots moistened and ensures that the roots can absorb enough water and nutrients for growth.

Rockwool as a growing medium comes in different forms and is widely used in greenhouses worldwide. A significant advantage is that rockwool cannot rot; however, it is important to monitor the pH with rockwool.

If the pH is too low, rockwool tends to lose its structure. In modern greenhouses, the pH of the solution is automatically regulated and adjusted.

Hydroponic rockwool is available in the following types:

- Rockwool cubes (for germinating seeds)

- Rockwool slabs (Rockwool cubes with young plants are placed on the slabs, and the roots grow through the block and into the slabs. The slabs are soaked with a nutrient solution).

Hydroponic coco coir

Did you know that coconut fiber can be used to grow plants? Coco fiber for growing plants is often called ‘coco coir’ and is widely used, as it helps the plant roots stay aerated throughout the growing cycle.

This ensures that the plant roots receive sufficient oxygen, which promotes the growth of the crop.

More plant based natural fibers are being used in a hydroponic system, as they are abundantly available in nature and they have unique properties such as being light weighted, relatively cheap and strong.

The biggest advantage of coco coir is that it is a natural product that is 100% degradable and has a lower carbon footprint. After the production season is over, the coco coir can be used to enrich neighboring fields for outdoor production.

A downside of coco coir is that the coconut fibers might come loose from the slab and damage the hydroponic system by causing blockages if the system doesn’t have a filter.

-

Using coconut coir for plants: coco substrate is also widely used for hydroponic production.

Hydroponic perlite

Hydroponic perlite is a volcanic mineral characterized by being lightweight and sterile. Perlite used for growing crops in a hydroponic system is valued for its aeration and drainage properties.

Perlite granule size differs, but often, they are around 2mm. The pH of perlite is around 5.6.

Hydroponic perlite fosters optimal root development, providing enough air in the root zone and can maintain a pH suitable for plant growth.

Perlite can be used as a growing medium in different systems such as the drip system and Ebb & Flow system.

In some cases, perlite bags/perlite slabs can be reused by small-scale farmers after the plants are harvested.

Perlite can be sterilized with hydrogen peroxide to kill plant pathogens.

-

Perlite can also be used as a hydroponic growing substrate. Perlite is a volcanic mineral and is relatively light.

What Can You Grow Hydroponically?

In the past, vegetables, fodder crops, cereals, fruits, flowers, and medicinal plants have been grown in hydroponic greenhouses. Even growing carrots hydroponically is possible.

Research and commercial greenhouses have shown that the crop yields in hydroponic greenhouses per area are higher than open agriculture yield per area.

In a (closed or semi-closed) greenhouse, the crops are, among other things, protected against unfavorable environmental conditions. Also, the nutrients are easily taken up in a hydroponic system, resulting in an increase in yield.

The yield in a hydroponic system can be further increased when artificial lighting is applied, and extra CO2 is introduced into the system.

Growing tomatoes indoors is particularly interesting, as in a mid-tech/high tech greenhouse environment, a yield of 40kg/m2 – 70kg/m2 is achievable. For comparison, the yield of open agriculture, usually won’t be more than 22kg/m2.

-

5 Benefits Of Hydroponics:

Implementing hydroponics in a greenhouse has its advantages and disadvantages. Here below, hydroponics pros and cons with some extra explanations are listed:

1) Year-Round Production possible

One of the main advantages of indoor hydroponic systems is that year round production becomes possible, removing the seasonal growing constraints. As the crops are grown in a controlled environment, consistent and reliable supply of fresh produce can be expected.

2) Maximized Crop Yields

Precise control over environmental factors, nutrient delivery, and lighting promotes accelerated growth and significantly higher crop yields compared to traditional cultivation methods.

3) Resource Efficiency

Water and nutrient recycling, along with efficient climate control, contribute to resource efficiency, making growing with hydroponic greenhouses a sustainable way to produce food, especially when green energy sources are used to heat and light up the greenhouses.

4) Clean products

As the vegetables and fruits do not grow in soil but in a nutrient solution, the growing environment is very clean. No dirt and no insects eggs present in the growing hydroponic medium.

5) Optimized Labor Productivity:

Growing in hydroponic systems, reduce the need for manual labor such as weeding. Also, with automatized systems, the plants automatically irrigated, correct amount of nutrients are given through the system.

This contributes to optimizing productivity and allows growers to focus on other things, such as strategic decision-making, to increase the yield even more.

Suitable hydroponically grown crops

It should be noted that not all crops are financially feasible to grow hydroponically. While growing lettuce hydroponically can be very profitable, the costs to operate a hydroponic system for fodder crops such as corn and barley are too high, especially considering these crops don’t have a high market value.

A List of the Best Vegetables for Hydroponics:

- Hydroponic tomatoes / hydroponic cherry tomatoes

- Hydroponic lettuce

- Hydroponic eggplant

- Hydroponic cucumber

- Hydroponic bell pepper

- Hydroponic chili pepper

- Hydroponic radish

- Hydroponic spinach

A List of Suitable Hydroponic Flowers:

- Pansy (edible)

- Marigold (edible)

- Violet (edible)

- Anthurium (Laceleaf)

A List of Suitable Hydroponic Fruits:

- Strawberry

- Melons

A List of Suitable Hydroponic Herbs:

Herbs are interesting as they have a short grow cycle, meaning they can be harvested quite quickly.

- Sweet Basil / Thai Basil

- Parsley

- Thyme

- Mint

- Oregano

- Black pepper

4 Challenges Of Hydroponics:

Besides the advantages of hydroponics, there are also some challenges associated with the usage of a hydroponic system in a greenhouse. Here below, we have summarized the cons of hydroponics and what can be done to solve these challenges.

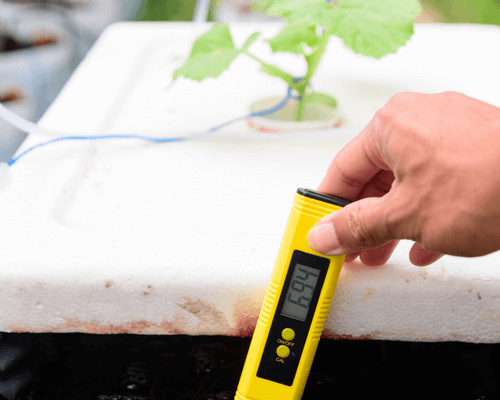

1) Nutrient Management:

- Challenge: Maintaining the right balance of nutrients in the hydroponic system and pH can be challenging if you don’t have the right equipments. Nutrient imbalances or deficiencies can lead to stunted growth, poor yields, and other plant health issues.

- Solution: Regular monitoring of nutrient levels and pH, adjusting the nutrient solution as needed, and using high-quality nutrient mixes can help overcome this challenge. In modern greenhouses, maintaining the right balance of nutrients, pH and EC (Electrical conductivity, says about how much ions of the nutrients are present in the nutrient solution) goes automatically.

2) Potential disease spread

- Challenge: While hydroponic systems can reduce the risk of soil-borne diseases in a well maintained greenhouse, the hydroponic crops are not immune to certain pests and diseases.

- Once a disease gets into the hydroponic system, it can spread to many plants through the nutrient solution which passes the root system. In a closed environment with a connected irrigation system and no disinfection machine, this can be a major risk for plant health.

- Solution: Implementing strict hygiene practices among workers, installing water disinfecting system (with UV light), installing insect nets at the windows of the greenhouse, regularly inspecting plants for signs of pests or diseases and optional: introducing beneficial insects (natural enemies of pests, such as parasitic wasps for caterpillars of butterflies and moths).

3) System Failures and Technical Issues

- Challenge: Hydroponic systems involve various technical components such as pumps, sensors, and climate control systems. Technical failures can disrupt the entire system and impact plant health.

- Solution: Regular maintenance, monitoring equipment functionality, and having contingency plans in place can minimize the risk of system failures. Training staff in troubleshooting and maintaining equipment is also very essential!

4) Cost of Initial Setup

- Challenge: The initial cost of setting up a hydroponic system, including infrastructure, equipment, and technology, is higher compared to traditional soil-based cultivation.

- Solution: While the upfront costs are significant, the long-term benefits and increased yields often justify the investment. Growers can explore different system scales and designs to find a balance that suits their budget and production goals.

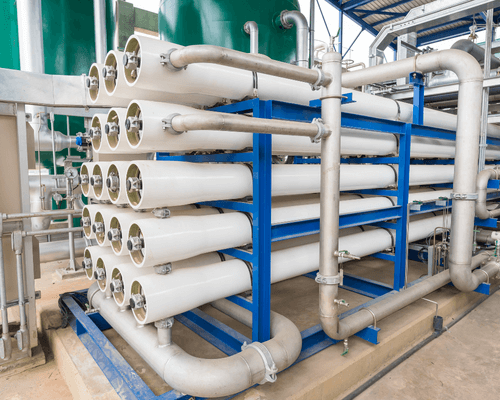

Reverse osmosis commercial systems in greenhouses

Usage of commercial reverse osmosis unit

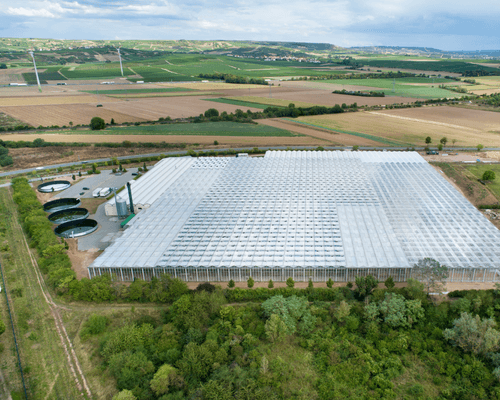

Most greenhouses have one or multiple rainwater collecting basins to gather water for use in the greenhouse. However, increasingly, reverse osmosis (RO) units are being installed in greenhouses worldwide to ensure a continuous water supply, even during long periods of drought.

In situations where the rainwater basin is empty, greenhouse companies will need to switch to groundwater or river water to provide the crops with enough water.

Reverse osmosis can increase the quality of water from a (deep) well, ditch, or rainwater to the desired standard. A general rule of thumb is that the cleaner the water entering the greenhouse, the lower the likelihood of accumulating undesirable substances in the greenhouse irrigation systems.

-

On the image, water collecting basins can be seen (left side). However, ocasionally, the collected water is not enough and ground water need to be used and cleaned with reverse osmosis for clean water in the greenhouse. Or to manage clean water

Using Commercial Reverse Osmosis for Sensitive Crops:

Commercial reverse osmosis systems are also used to remove specific minerals from the water. Strawberries are very sensitive to silicon, which can result in white and colorless fruits when the concentration of silicon is too high.

Therefore, for professional largescale strawberry producers, installing a commercial reverse osmosis unit (also called industrial RO systems) is advised.

Propagation Plants in a Hydroponic System:

In a hydroponic growing system, it is very easy to propagate plants. Many professional greenhouse nurseries also use hydroponics to grow their young plants after sowing, till they are big enough to be transferred to a commercial greenhouse (in the case of tomatoes in the Netherlands).

Commercial Hydroponics System:

Commercial hydroponics systems have emerged as a new and innovative approach to cultivating crops efficiently since their introduction about 50-60 years ago.

Switching from soil-based methods, commercial hydroponic growers use new scientific knowledge and technologies to produce crops efficiently with large-scale hydroponic systems.

Growing hydroponically offers a strategic and more sustainable solution to the increasing demand for fresh produce by 1) maximizing efficiency, 2) minimizing resource usage (water, nutrients, pesticides), and 3) providing year-round crop production.

Dutch greenhouse systems provide solutions for horticulture professionals and growers worldwide.

How To Grow More With Hydroponics In A Greenhouse?

Dutch hydroponic greenhouses are renowned for their high production per ground area, as they are highly efficient.

The Netherlands faces a labor shortage, high energy and gas prices, and limited land, so the greenhouses have evolved to be very efficient in terms of yield.

Below, common components and equipment of a Dutch commercial hydroponics greenhouse are listed. This list provides an idea of the types of commercial hydroponics equipment and hydroponic supply needed to operate optimally 24/7.

use cimate Control Systems (with climate computers):

- Commercial hydroponics greenhouses are equipped with advanced climate control systems. This includes automated ventilation, heating, and cooling systems to maintain optimal temperature and humidity levels.

- Plants are living organisms that are very sensitive to environmental changes, so keeping the environment temperature and humidity stable is important.

- High-tech sensors and computerized controls enable precision in managing environmental conditions, ensuring crops to grow optimally year-round.

understand hydroponic Growing Systems:

- Dutch greenhouses use hydroponic growing systems to grow crops and flowers. Nutrient film technique (NFT) for vine crops and strawberries and deep water culture (DWC) for lettuce production are commonly used.

- These systems provide plants with a precisely controlled nutrient solution, promoting faster growth, higher yields, and resource efficiency.

Apply Water Management:

- Water scarcity concerns are addressed with a hydroponic growing system through efficient water management systems, incorporating recycling and reuse practices.

- In an open field (without drip irrigation) the estimated amount of water that is needed to produce 1 kg of tomatoes is 100-300 liter. While in a Dutch advanced controlled glasshouses with CO2 and a closed hydroponic system it is just 15 liter water per kg tomatoes. When it is a closed greenhouse (without windows), the amount of water needed is just 4 liters!

- Dutch hydroponic greenhouses efficient irrigation technologies, such as drip irrigation or ebb and flow systems, ensuring precise and resource-conscious water distribution.

make use of Plant Lighting Solutions:

- To compensate for insufficient natural sunlight, Dutch commercial hydroponics greenhouses integrate efficient lighting solutions. Previously, HPS (High-Pressure Sodium) lights were used, but nowadays more LED grow lights are installed to reduce energy consumption of the greenhouse.

- LED Light spectrum and intensity can be tailored to specific crop requirements, maximizing photosynthesis and accelerating growth.

Install Greenhouse Hygiene Stations and follow best Practices:

- In Dutch commercial hydroponics greenhouses, maintaining strict hygiene is the standard. Hygiene stations are often strategically placed at entry points to ensure that everyone, including personnel and visitors who are entering the greenhouse, do not take plant viruses and other plant diseases with them.

- Workers are often required to undergo hygiene procedures, such as foot baths and hand sanitization, to prevent the introduction and spread of diseases that can affect plants.

use climate Screens:

- Climate screens, also known as shade or energy screens, are essential components in Dutch commercial hydroponics greenhouses. These retractable screens are used to regulate light intensity and the temperature in the greenhouse.

- Climate screens contribute to creating optimal growing conditions and improving energy efficiency within the greenhouse.

They are particularly crucial in managing excess solar radiation during peak sunlight hours and in keeping heat inside the greenhouse during colder periods during the night

Use Water Filtration and Drain Water Disinfection Systems:

- To reduce the usage of water in greenhouses and potential pest outbreaks, Dutch commercial hydroponics greenhouses reuse water in the hydroponic systems by disinfecting it.

- Advanced water filtration systems, including sand filters and UV disinfection units, are commonly integrated to clean the drain water which have flown in and out of the hydroponic system. Without these systems, it won’t be possible to reuse the water safely, safeguarding plant health.

- These systems remove impurities and pathogens from the water, ensuring a clean and disease-free nutrient solution.

6 Types of hydroponics growing systems

There are in total 6 different types of hydroponic systems, which each differ in mechanism and complexity.

The best hydroponic system depends on the scale and the purpose of the production system. Also, where you want to grow also has influence on the choice of the right system.

Here, we explain for each of the six hydroponic systems (Deep Water Culture, Wick system, Aeroponics, Nutrient Film Technique (NFT), Ebb & Flow and Drip system) how they work and the pros & cons.

Deep Water Culture is considered one of the most straightforward hydroponic cultivation systems in this list.

In a container filled with water and the necessary plant nutrients (minerals), plants are placed in holders where the roots come in contact with the nutrient solution.

The majority of the plant’s roots are submerged in the water, while the plant’s leaves extend above the substrate (rock wool/coco coir/perlite).

Although Deep Water Culture is highly user-friendly, it is essential to ensure an adequate supply of oxygen in the water. This can be done by using an air pump (and diffuser stones in smaller systems) to introduce enough oxygen into the water.

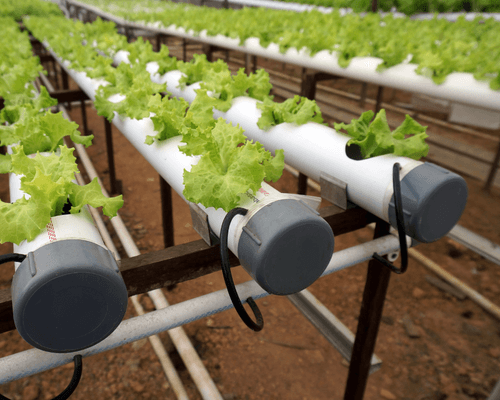

In commercial hydroponic systems in greenhouses, Deep Water Culture is often used for lettuce production, where lettuce is placed on floating plates with their roots hanging in the nutrient solution.

The Wick system operates on capillary action (=nutrient liquid rises up against the gravity force). Beneath the plants, there is a water reservoir containing dissolved nutrients.

Through the use of a “wick,” (also known as a bundle of fibers), water with nutrients is drawn upward to the roots.

A major advantage of this system is that it does not require electricity for a water pump or an air pump, as natural physical forces take care of the up flow of the nutrient water.

However, a drawback is that this system is not suitable for plants with high water and nutrient demands.

This is primarily because the system cannot deliver a sufficient amount of water to the plants within a short time of period. For plants such as tomatoes with substantial water needs, optimal growth cannot be achieved in this system.

On the other hand, this system is suitable for home-grown herbs and has the added benefit of being energy-efficient.

Fine mist is regularly sprayed onto the roots through the use of very fine sprayers.

The connected water pump circulates water through multiple tubes, and from these tubes, fine misting nozzles provide the roots with nutrients and water.

The spray method in this system results in highly efficient nutrient absorption. Furthermore, since the roots are hanging in the air, they consistently have access to ample oxygen.

The abundance of oxygen in the environment significantly promotes the growth of plants in this system.

The vertical farm company, “Aerofarm”, uses this type of hydroponic system to grow their herbs and microgreens.

A pump pumps the water up and the diagonally placed PVC (Polyvinyl chloride) pipes or steel gutter in which the plants (/growing slabs with the plants on top) are placed, ensure that the water can flow to the lowest point.

Once there, the water returns to the water reservoir via a water pipe.

The nutrient solution flows quietly and uninterruptedly through the tube, and there is always a layer of water available for the roots.

This system also contains a lot of oxygen due to the continuous flow of the water.

The Ebb and Flow system, which is usually also called Flood and Drain system, is a hydroponic system that can be built fairly easily, but above all relatively cheaply.

With this system, the plants are placed next to each other in a large container and the roots receive water periodically when the water level rises before the nutrient solution flows back to the water reservoir again.

In many other hydroponic systems, the roots are nearly continuously surrounded with water/nutrient solution.

In this system, the water only reaches the roots periodically, but the roots still in the nutrient solution several times a day.

This system is a bit like watering plants using a watering can. Instead of refilling the watering can again and again, the water drips from a water reservoir tube.

The hydroponic Drip System is globally widely used and there are two variants: one that is suitable for recirculation and one that is not circulatable.

The circulatable drip system is used in greenhouses or in a closed system. The nutrient solution is then reused and pumped around.

In the non-recirculating variant of the drip system, water is not pumped back to the reservoir. Instead, the water that has already passed the roots is drained. Not recirculating has a significant advantage for the grower because there is no need to consider the nutrient and pH values in the reservoir when recirculating the “used” nutrient solution.

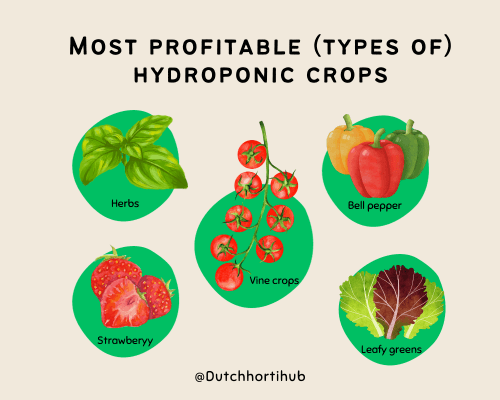

What is the most profitable plant to grow hydroponically in a greenhouse? And why?

Choosing the right crop to grow in a greenhouse will determine the final profitability of your hydroponic business, short term and long term.

The most profitable crops to sell (we have excluded medicinal cannabis here), is often related to short growing cycle and market demand.

Below, we have listed some of the most profitable plants to grow hydroponically here below and why they belong to profitable crops. They are not sorted based on their profitability.

1) Herbs (Basil, Cilantro, Mint):

- Reason: Herbs have a high market demand, and their short growth cycles make them suitable for hydroponics. They also require relatively small spaces, allowing for efficient use of indoor farming (and especially for vertical farming systems).Fresh, locally grown, and high quality herbs are sought after by restaurants, farmers’ markets, and consumers, contributing to their profitability.

2) Leafy Greens (Lettuce, Spinach, Kale):

- Reason: Leafy greens are popular choices due to their quick growth, consistent demand, and suitability for hydroponic systems.They can grow really fast in nutrient-rich indoor environments and are well-suited for any kind of indoor farming (mid-tech greenhouse, high-tech greenhouse and high-tech vertical farming). With a continuous harvest cycle, growers can maintain a steady income stream.

3) Tomatoes

- Reason: Tomatoes are in constant demand, and hydroponic cultivation allows for precise control over their growing conditions. This control results in higher yields and better-quality produce than field grown tomatoes.Also, if tomatoes can be grown locally, they don’t need to be imported from other countries. Hydroponically grown tomatoes also tend to mature faster, and the tomato plants have a longer growing period, allowing for more fruits harvests and therefore increased profitability.

4) Bell Peppers:

- Reason: Similar to tomatoes, bell peppers are sought after in the market and benefit from the controlled environment of hydroponics. With proper care, hydroponically grown bell peppers can have higher yields and quality compared to traditional soil cultivation.

5) Strawberries

- Reason: Hydroponic strawberry cultivation offers advantages such as reduced disease risk, better fruit quality, and extended growing seasons. The market demand for fresh, locally grown strawberries, especially in areas with shorter growing seasons, contributes to their profitability.

How hard is hydroponic growing?

How hard growing crops hydroponically, depends on factors such as the scale of the system, how professional the hydroponic greenhouse is, the complexity of the chosen cultivation method, how much of the processes are automatized and the type of crops being cultivated.

Having experienced growers or hiring greenhouse consultants can help you to realise your pre-determined optimal yield quicker.

Here’s a breakdown of the factors that influence the difficulty of hydroponic growing:

Depends on: Scale of the System

- Small-Scale Systems: Home-based hydroponic systems are relatively straightforward and can be managed by beginners with minimal experience. (the types of systems are explained below)

- Medium to Large-Scale Systems: Commercial hydroponic operations with more extensive infrastructure and automation require more expertise in terms of system design, nutrient management, and environmental control.

- Aeroponics and hydroponic system in a vertical farming setting can be more challenging, it requires a deeper understanding of nutrient dynamics, system maintenance, and potential issues.

- But when you get it started, the hydroponic system is quite straightforward when you have the right equipment and technologies helping you to operate.

Depends on: choice of type of Crop

- Growing crops like lettuce, spinach, and herbs hydroponically tends to be less challenging.

- However, cultivating fruiting crops such as tomatoes, peppers, or strawberries can be more complex due to the longer growing periods, specific nutrient requirements and more incidence of pests and diseases among these crops.

Depends on: Level of experience and Knowledge

- Beginner growers: New growers may find hydroponics at the beginning to be a bit challenging, especially when learning about nutrient solutions, pH levels, and environmental control.

- Experienced Growers: Growers with experience in traditional soil-based cultivation or a background in horticulture may find growing with hydroponics less challenging or even easier to work with.

Depends on: available Technologies and Automation

- The level of technology and automation available in hydroponic systems can significantly impact the ease of hydroponic growing.

- Advanced technologies, such as sensor-driven monitoring systems, automated nutrient dosing, and climate control systems, have become more accessible and available.

- These technologies help growers to have automated control of the hydroponic growing system in the greenhouse, which makes it easier to maintain optimal growing conditions in the greenhouse.

- While the integration of technology adds a layer of complexity, it also offers precision and efficiency, ultimately enhancing the overall manageability of hydroponic systems.

Growers can choose the level of automation, depending on the expertise and preferences, from basic setups to high tech, fully automated environments.