Greenhouse automation with Greenhouse Climate Control Systems: What greenhouse climate control computers can do

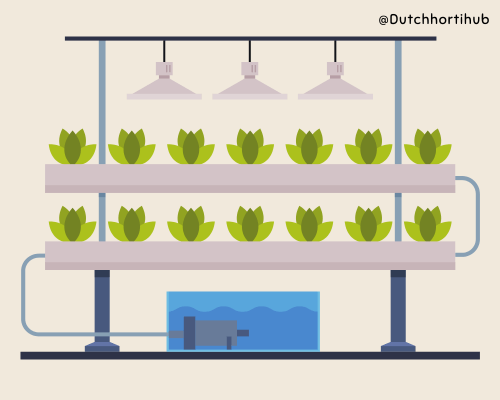

No matter whether you are growing crops in mid-tech plastic tunnels, high-tech glass greenhouses, or cultivating lettuce indoors with only artificial lighting, climate control greenhouse technology is absolutely essential, regardless of the size of the greenhouse

With a greenhouse climate control computer, a more stable growing environment can be created, which ensures a more constant and higher yield throughout the production cycle. Also, energy usage for heating, cooling, and lighting can be optimized with self-learning system algorithms of the latest greenhouse climate control systems.

On this page, we will provide a clear explanation of what a greenhouse climate control computer is. We’ll also discuss the advantages of greenhouse climate control systems and how variables such as greenhouse temperature can be regulated keeping fluctuations as low as possible.

We’ll highlight some important reasons why growers should consider implementing greenhouse control systems, the background information on the software and hardware of smart greenhouse computers.

Also, we will show what can be automatically controlled with a greenhouse climate control system and the steps towards autonomous greenhouses.

Table of contents:

- Table of contents:

- What is greenhouse climate control?

- Why would you need a greenhouse climate control system?

- Automation in Greenhouse with Climate Control Systems saves Time, Money and Labour Hours

- The introduction of the first greenhouse climate control systems in the world

- From simple PC’s in greenhouses to controlling growing conditions from smartphones

- How do Greenhouse Climate Computers work?

- The Differences Between Greenhouse Climate Computer And Greenhouse Climate Controller

- Optimize Greenhouse Environmental Conditions with Automated Climate Control

- Greenhouse sensors – Types of sensors in the greenhouse

- Indoor agriculture in 2024 – Data Driven Growing in Smart Greenhouses

- 11 Advantages of Operating a Climate Controlled Greenhouse

- What can Greenhouse Environmental Control Systems control?

- Case study – Autonomous Greenhouse Challenge: the future of growing with Greenhouse Climate Computers

- Growing greenhouse crops based on Plant Empowerment – “Het Nieuwe Telen”

- Dutch Greenhouse Climate control computers

- FAQ about greenhouse environment control & climate controller for greenhouse systems

What is greenhouse climate control?

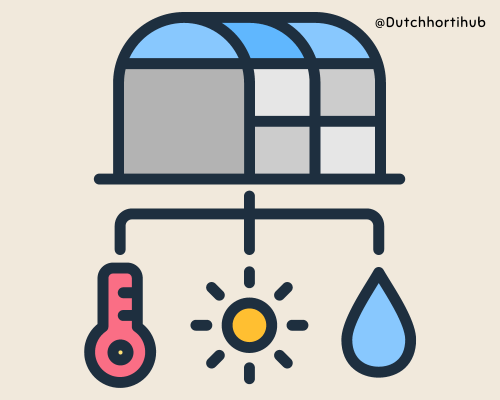

Greenhouse control is the management and regulation of indoor environmental growing conditions in a greenhouse, so that plants can grow optimally and healthy.

Greenhouses are structures designed to create a controlled environment for plants by manipulating factors such as temperature, humidity, light, and ventilation.

So that, independent of outdoor conditions, crops can still be grown. Even in the winter or up north in Iceland, where tomato production in professional greenhouses would not have been possible without producing it in greenhouses.

Greenhouse controllers are used to maintain these factors within specific ranges to create an ideal growing environment for crops and flowers.

What are greenhouse climate control systems?

The climate in a greenhouse is managed by a greenhouse climate control system. Greenhouse climate control systems monitor and regulate factors in greenhouses so that plants can grow optimally. This is done by a central greenhouse climate computer and greenhouse controllers.

Optimizing greenhouse production requires a smart approach, ensuring maximum yield and perfect crop quality. Achieving these goals involves comprehensive control over the greenhouse climate.

Since the first Dutch greenhouse climate computer was introduced 50 years ago, smart greenhouse climate control systems have helped growers around the world grow profitable crops and ensure optimal growth of their crops in greenhouses.

Nowadays, wireless-controlled greenhouse automation enables remote control, eliminating the need for on-site management. Whether operating in a predominantly hot or cold winter climate, greenhouse temperature control systems empower growers to cultivate any greenhouse crop, anywhere in the world.

To future-proof greenhouse businesses, Dutch greenhouse automation software and climate control greenhouse systems are continuously updated, providing a secure and smart system that uses the latest horticulture growth algorithms for optimal yield prediction and production.

Why are greenhouse climate control systems being used by high yield growers?

Greenhouses with climate control are the standard in modern agricultural practices. In the Netherlands, 96%-98% of all greenhouses are equipped with a greenhouse control system.

In a computer-controlled greenhouse, the yield is easier to predict, based on the data tracked by sensors and human errors in greenhouse operation are reduced.

In the Netherlands, a greenhouse climate control system is essential due to the extremely high operational costs. Ensuring that all environmental conditions are optimized contributes to the profitability of greenhouse businesses.

Using a greenhouse climate computer automizes the greenhouse operation.

Why would you need a greenhouse climate control system?

Imagine yourself as a tomato grower in a modern glass greenhouse of a 1-hectare (100m x 100m) hydroponics farm, cultivating tomatoes in the US without any climate control system. Around you, there are young vine tomato plants growing nicely in rows.

To grow tomatoes optimally throughout the year, your greenhouse is equipped with LED lights for artificial lighting, CO₂ to maintain a high photosynthesis rate, misting to control humidity levels, fans and roof windows for temperature regulation, and heating when needed.

Energy screens are also installed to reduce incoming radiation, preventing overheating and loss of heat during cold evenings. The greenhouse water and nutrient regulator connected to the hydroponic system ensure the tomato plants receive sufficient clean water and nutrients for their roots.

The final yield of these tomato plants is highly sensitive to environmental changes, so the growing conditions should be as best as possible if you want to achieve a high yield.

In this 1 hectare tomato greenhouse, there is only you to control the growing climate conditions.

Depending on the day and weather conditions, you need to decide by yourself whether and when the windows should be opened, how much CO2 you should give in the greenhouse, when the LED lights should be turned on, when you should start misting the greenhouse to keep the humidity level optimal, whether it is a good idea or not to open the energy screens, how much more nutrient you should give to the plants….. and the list goes on…….

Would you want to take on all these responsibilities and decision-making, all of which contribute to determining the final yield of the tomato plants? Especially when you know that every bad decision will cost your farm money?

Probably not. Also, regulating all these things in the greenhouse by yourself would cost you a lot of time. Most of the time, you would be making choices based on the guesses you made about the greenhouse conditions and not on the actual greenhouse condition.

What if there was a computer regulating all these things in the greenhouse?

It would turn the lights on based on the light intensity, provide the exact amount of CO₂ throughout the day to prevent fluctuations, deliver the optimal amount of nutrients to the tomato roots for growth, heat the greenhouse only when needed, and use smart algorithms based on collected data to make reliable, data-driven decisions.

Thankfully, it’s 2024, and these smart greenhouse climate control computers do exist, and they make climate controlled greenhouses possible.

Greenhouse climate control systems are available for small, medium, and large sized greenhouses. Making use of climate control greenhouse technologies is investing in the current and future profitability of the greenhouse.

Automation in Greenhouse with Climate Control Systems saves Time, Money and Labour Hours

Instead of running around the greenhouse to regulate all the different elements and making uncertain decisions throughout the day, you can now sit behind a laptop with a nice cup of coffee in the greenhouse and observe the smart climate control computer managing all those events for you.

With a greenhouse climate control system, tomato crops can grow optimally 24/7 with only limited human effort. This allows you to focus more on other aspects of greenhouse management.

The above explanation precisely illustrates why you would need a greenhouse climate control system for your commercial greenhouse.

What does it mean to grow crops in a controlled environment?

Growing crops in a controlled environment means that the crops are, to an extent, protected from the outdoor environment. The degree of protection depends on how modern the greenhouse is.

In a controlled environment (in greenhouses or indoor climate chambers), the growing conditions are carefully regulated by using technologies like climate control, artificial lighting, and irrigation.

Growing in a controlled environment optimizes environmental factors such as temperature, humidity, and nutrient levels to enhance plant growth and productivity.

Growing crops indoors has many benefits, such as year-round cultivation of high-quality crops, reduction of pests and plant diseases, and increased efficiency of water and nutrient usage.

Brief history of the development of greenhouse climate control systems.

The greenhouse climate computers that we know today were developed as a result of technological advancements and consumer demand for out-of-season and non-native greenhouse products.

In the 1970s, the Netherlands faced a major energy crisis. To reduce energy usage in greenhouses, a new research collaboration was initiated, involving scientists from various disciplines in the country.

Not only were physicists involved, but also plant physiologists, engineers, and horticulture specialists. This collaboration led to an increase in new insights and knowledge on greenhouse production.

Through interdisciplinary and multidisciplinary cooperation, the first greenhouse climate computers were developed and introduced by the Dutch.

Before the introduction of digital climate control systems, the control of greenhouse systems was primarily handled by the grower.

At the beginning, managing the greenhouse growing environment was done by using thermostats to measure the temperature of the greenhouse environment. This was later replaced by analogue electronic controllers.

In the 60s, simple analogue climate control systems were used to control heat and ventilation. In the 70s, computer technologies were introduced in the greenhouses.

Microprocessors increased the flexibility because more complex control algorithms could be implemented and were cheaper to use to control multiple compartments compared to the analogue system. Also, from then, it started to become possible to register climate conditions in the greenhouse.

The introduction of the first greenhouse climate control systems in the world

It was in 1974 that the first digital greenhouse climate control system in the world appeared on the Dutch market, making the lives of greenhouse growers easier ever since.

This system operated independently, overseeing any number of sections in the greenhouse. There was a central computer to which sensors and actuators (devices that are responsible for carrying out actions based on received signals), were connected.

This first greenhouse climate control system had a central host computer which was connected to local measurement and control processors. Calculations of the control algorithms were all performed together with data handling, graphics and greenhouse alarms on the host computer.

This greenhouse climate computer measured the sensor signals and activated the relays (control the flow of electrical current of a circuit) for the valves (part of flow control component) and ventilators in the greenhouse.

Thanks to the decreasing cost of microprocessors, significant advancements have occurred in both greenhouse hardware and software since the introduction of greenhouse climate computers.

With the automatic adaptation of control parameters to the actual greenhouse situation becoming possible, control algorithms have been continuously improved.

From simple PC’s in greenhouses to controlling growing conditions from smartphones

It could not be imagined now, but personal computers (PC) were rare some decades ago. In the late 70s, more greenhouses possessed and made use of PC’s.

This, together with the development of improved user interfaces of the greenhouse software, made transferring and analysing of (real time) greenhouse climate data by the growers possible.

Climate control systems have evolved to more complex systems, especially since more greenhouse equipment was introduced that needed to be automatically controlled as well in commercial greenhouses, depending on the indoor and outdoor conditions.

These equipments include: energy screens, ventilation, CO₂ enrichment, artificial lighting.

Nowadays, climate computers can be connected to the computer controlling nutrient solution and the management computer, for example.

Data from the climate computer can even be sent to growers’ mobile phones, resulting in the growers can control the greenhouse conditions anytime and anywhere. Even from a large distance or abroad.

How do Greenhouse Climate Computers work?

Greenhouse climate control has evolved in the last 50 years from controlling the environment manually to digitally. The Dutch researcher Strijbosch was an important person that had contributed enormously in the greenhouse control system development.

The findings of his works (among others recording the climate control strategies of growers in the Netherlands), still lay the foundation for the current greenhouse climate control systems and the greenhouse computers.

Greenhouse control systems consist of a hardware and a software part, both work together to control an optimal and uniform greenhouse environment for the crops.

Making informed choices on crop growth conditions is important. The amount of decisions a grower needs to make in a greenhouse increases with the complexity of the greenhouse.

In a modern greenhouse, there are more elements that need to be controlled compared to a low-tech greenhouse. Based on pre-set points, many greenhouse operation choices are handled by a greenhouse computer program.

When using a greenhouse climate computer, the system will ask the grower to enter input set point values for the greenhouse ‘goal’ variables – such as what is the preferred temperature, air humidity, CO₂, light intensity in the greenhouse.

The grower will also indicate how much the greenhouse condition can differ from the pre-set value. The less the differences that can take place throughout the day, the more energy it is needed to regulate those factors in the greenhouse.

Greenhouse climate computers work with feedback loops

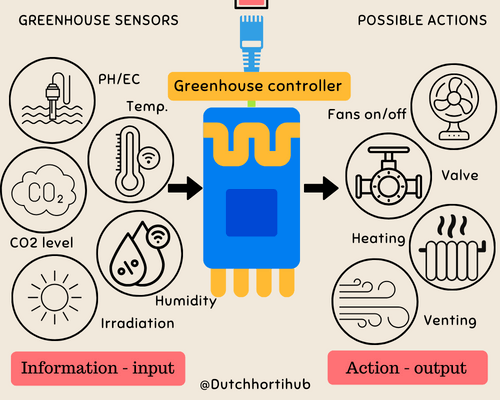

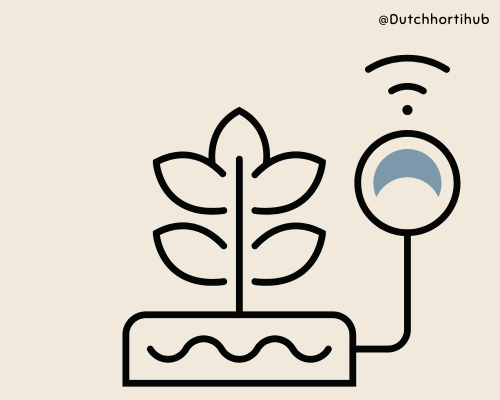

The data of the sensors are collected and sent to the greenhouse controller for feedback. For example for the CO₂ environmental variable: the CO₂ meter is the device that measures the CO₂ concentration in the greenhouse compartment.

When the compartment has an optimal CO₂ value, the CO₂ value won’t be altered. However, when the CO₂ contraction is suboptimal, the CO₂ controller will allow an increase of the amount of CO₂ concentration in the compartment.

Hardware of greenhouse climate control systems

The hardware of a greenhouse climate control system includes the physical components, such as sensors, actuators, and controllers, responsible for monitoring and regulating environmental conditions.

Software of greenhouse climate control system for professional greenhouses

The software of the greenhouse control system is about the programs and algorithms that interpret greenhouse data from sensors, make decisions, and control the hardware components to maintain optimal conditions for plant growth.

The Differences Between Greenhouse Climate Computer And Greenhouse Climate Controller

The terms “greenhouse climate controller” and “greenhouse climate computer” are related, but there are some subtle differences between these two terms.

Greenhouse climate computer

A greenhouse climate computer is a system that includes not only (mechanical) controllers for individual environmental factors (such as regulating the humidity in the greenhouse) but also a central computer and software platform that integrates and manages the overall greenhouse environment and performance.

A greenhouse computer coordinates and controls multiple controllers through a central computing unit or software.

Greenhouse controller

What is a greenhouse controller? A greenhouse climate controller is a device that controls a specific environmental factor within a greenhouse, such as temperature or humidity in a greenhouse compartment.

Greenhouse controllers have sensors to monitor the environmental conditions within the greenhouse growing compartment, allowing the greenhouse controller to make informed adjustments to maintain optimal growing conditions.

Optimize Greenhouse Environmental Conditions with Automated Climate Control

To answer the question of how do greenhouses control climate, the answer for commercial greenhouses is often: make use of a greenhouse climate control system. No matter how big or small a greenhouse is.

Identifying the limiting growing factor in the growing environment

With a greenhouse environmental control system, many of the important variables can be controlled to ensure an optimal growing condition for the crops. Creating an optimal growing environment for the plant involves identifying and optimizing the limiting factor in the greenhouse.

Understanding what the limiting factor is and what kind of impact the limiting factor has on the growing condition for the greenhouse crops is very important.

Greenhouse climate control systems optimize growing conditions by ensuring that all climate, nutrient, and crop growing conditions are optimal.

The limiting factor is a certain factor that has a value that is not optimal for plant growth, resulting in a reduction in the total crop yield.

To illustrate what a limiting factor is, we provide the following example. Imagine it is a sunny day with enough sunlight for the crops in the greenhouse. The humidity level is perfect, and the plants have enough nutrients to grow optimally.

However, as the windows have been opened and the plants have used a significant amount of CO₂ to grow, the CO₂ concentration in the greenhouse has dropped significantly and is around 400 ppm (parts per million).

We know that to allow a plant to photosynthesize at a high rate, 1000-1200 ppm CO₂ should be supplied. As there is plenty of sunlight, water/nutrients to drive photosynthesis but a lack of CO₂ in the greenhouse, CO₂ is the limiting factor in this example that prevents the plant from having a high photosynthesis rate, causing a reduction in the final yield at that moment.

A good climate control system manages and improves the limiting factor first, as that will immediately improve the yield. When that certain factor is optimized, then the climate computer will proceed with optimizing the other limiting factors until all have reached their optimal value.

Of course, a good greenhouse program works based on weighing the cost of improving the limiting growing factor with the expected increase in income. In the following sections , we will be discussing controlling the temperature, humidity, cooling, lighting, and CO2 supply in the greenhouse.

Control temperature with a greenhouse climate controller

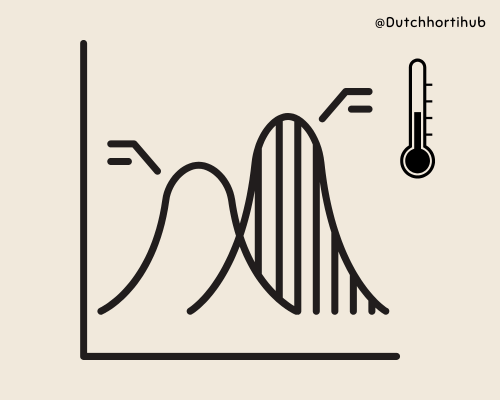

The temperature in the greenhouse is maintained with a climate computer using the principle that the temperature should be between a minimum temperature (lower than this temperature, heating will need to be turned on) and a maximum temperature (higher than this temperature, ventilation will need to occur to cool down the greenhouse environment).

Greenhouse temperature control with a greenhouse climate control computer automatizes this process.

These minimum and maximum temperatures are pre-determined by the grower, and the climate computer knows that.

Also, a deviation width/band is determined. It controls the extent of the reaction that the climate computer needs to take when the temperature is below or above the pre-set value and the deviation band.

Knowing how much the value deviates from the pre-set value is important. For example when the greenhouse temperature is just 3 degree Celsius above the preferred temperature greenhouse value, the opening in the roof should be less opened compared to if the average greenhouse temperature is 10 degrees Celsius above the growing optimum. In that case, the windows should be more open.

Creating a different temperature between day and night

In the evening, the maximum temperature should be lower in the greenhouse to create a ‘natural’ day and night temperature difference, as that is needed for the plant to grow and develop normally.

Flexible greenhouse climate control to improve plant growth and plant well-being

A very important element that the good greenhouse climate computer has, is when it allows flexibility.

When the climate computer knows that it has been a sunny day with lots of hours of sunshine, it should allow the night temperature in the greenhouse to be slightly higher compared to an average day. As after a sunny day, a lot of sugars have been produced in the leaves of the plants.

The night temperature of that day should be slightly higher, so that those extra sugars can be properly transferred out of the leaves to other parts of the plant at night.

To control the greenhouse temperature effectively, it should have flexible set points and take daily environmental conditions into account. This means that good greenhouse climate control does more than merely maintaining the pre-set temperatures as well as possible

Greenhouse temperature fluctuations – Using Temperature integration

A full-grown crop can actually tolerate short term temperature fluctuations quite well. Research has shown that the growth (biomass increase) and development (changes in stages of the plant) of the most important greenhouse crops (tomato, cucumber, bell pepper) are actually determined by the mean of temperature of several days (long term) rather than the temperature of just 1 or 2 days (short term).

This provides the possibility to work with temperature integration in the long term. For example: crops will tolerate the compensation of a 24h temperature of 19°C if the temperature is 21°C the following day; to obtain a 24h temperature of 20°C.

This however, can not be done for extreme temperatures such as 30°C on one day and 10°C the other day.

Best temperature to grow tomatoes in automated greenhouses

Dutch researchers have found that the best average temperature to grow tomatoes in a greenhouse is around 24°C. This temperature can (and should) fluctuate throughout the day.

The development of tomatoes responds to the 24h mean temperature. Meaning that the environmental temperature in the tomato greenhouse can be slightly higher during the day, when the temperature in the evening is below 24°C. A 26/22°C day and night temperature gives an average temperature of 24°C.

Please note that the temperature integration is only possible within the temperature range where the temperature depends linearly on temperature.

Allowing a fluctuating temperature range in greenhouses saves energy

Modern greenhouse climate computers allow temperature integration, and this helps growers to save energy.

Strictly controlling the temperature in the greenhouse costs a lot of energy compare to letting the temperature to fluctuate a bit throughout the day.

Controlling the temperature strictly is under some conditions not necessarily (because the plant can tolerate it) and in this case allowing the temperature to fluctuate will benefit the grower in terms of saving energy costs.

Of course, the right balance between energy costs and additional yield will need to be found.

Greenhouse sensors – Types of sensors in the greenhouse

For a climate computer to make accurate predictions and decisions, it needs to be able to receive data from sensors inside and outside the greenhouse.

Besides temperature sensors, other greenhouse sensors should also be included. Such as humidity sensors, CO₂ sensors, Photosynthetic Active Radiation sensors inside the greenhouse, radiation sensors for measuring outdoor global radiation, an anemometer for measuring wind speed, and a wind direction sensor so the climate computer knows from which side the wind is coming.

The outdoor sensors are also referred as the ‘weather station’.

Greenhouse sensors should be protected

In each greenhouse compartment, the temperature sensor, humidity meter (measuring the actual humidity and the relative humidity) and CO₂ meter (when CO₂ is being supplied in the greenhouse), should be present in a protected ventilated box.

In the greenhouse, those boxes are usually white and are hanging down from the ceiling.

The ventilated metal box around these sensors protects the sensors against solar radiation and other radiation that might unintentionally heat up or influence the sensors.

Control Humidity – Greenhouse humidity control with a psychrometer in automated greenhouse

The humidity in a greenhouse can be measured with a psychrometer and is connected to the greenhouse climate computer to assess the humidity and relative humidity in the greenhouse. The psychrometer measures the quantity of water vapour in the air.

Having the correct humidity level is essential for creating optimal growing conditions for plants. When the humidity is too high, it can increase fungi and bacterial incidence, harming the crops or reducing evapotranspiration by plants, which then directly affects the photosynthesis rate.

When the air humidity is too low, it can lead to excessive moisture loss of the crops to the environment (decreased water use efficiency) and reduced plant growth.

The principle of the psychrometer is based on the cooling effect of water evaporation. The meter consists of two parts: a dry bulb thermometer and a wet-bulb thermometer.

The dry bulb thermometer is a standard thermometer that measures the actual air temperature. The wet-bulb thermometer is covered with a wet cloth.

When air flows over the cloth, water will evaporate, causing the temperature to drop (evaporating costs energy). The lower the humidity is in the air, the greater the difference will be between the two temperatures. The difference in temperature is used to calculate the relative humidity in the air.

What should the humidity be in a greenhouse?

The humidity for greenhouse production should be kept between the two extremes (with a relative humidity ranging from 70% to 94% at 25°C/77°F) as plants may start to suffer when the humidity is either too low or too high.

Low humidity level in the greenhouse

Low humidity in the greenhouse means a relative humidity (RH) of 70% or lower. The dry air causes the plants to transpire a lot and is sensed by plants as stress. To reduce water transpiration, plants will start to close their stomata (opening in leaves).

Because of the closure, gas exchange is reduced and there is less inflow of CO₂ and outflow of O₂.

This increased stomatal for CO₂ has a direct negative effect on the leaf photosynthesis rate. Low humidity also leads to smaller leaves because the cell elongation is reduced.

High humidity level in the greenhouse

More often, greenhouse crops suffer more from too high humidity than from too low humidity. A humid greenhouse should be dealt with as soon as possible.

Fortunately, greenhouse control systems can measure and control humidity in greenhouses effectively. A relative humidity above 94% reduces the transpiration rate of plants and increases stress sensed by plants.

Control CO₂ level with a Greenhouse CO₂ meter

The CO₂ meter measures the CO₂ concentration in the greenhouse air. In greenhouses, the CO₂ level is expressed in parts per million (ppm).

As the level of CO₂ in the greenhouse has to a certain extent a direct relationship with the photosynthesis rate of the crop, measuring and tracking the CO₂ level in the greenhouse with a CO₂ ppm meter is essential.

The CO₂ concentration in air is currently 421 ppm (=atmospheric CO₂ concentration). Often, there is a lack of CO₂ in the greenhouse. With a CO₂ meter, growers can determine when and how much CO₂ should be added.

How does the Greenhouse CO₂ sensor work?

CO₂ levels are commonly measured using a Non-Dispersive Infrared (NDIR) sensor, which gauges the amount of infrared light absorbed in the air. The absorbed infrared light is proportional to the concentration of CO₂ in the air.

To drive the photosynthesis rate of crops, often a CO₂ concentration of 1000-1200 ppm is given, as additional CO₂ application significantly benefits crop growth. Supplying CO₂ in greenhouses can increase the growth rate and yield by 15-30%

Above 1200 ppm carbon dioxide concentration, saturation responses can occur and might start negatively affecting crop growth as stomata can start to close, reducing gas exchange.

3 Ways to Increase CO₂ in Greenhouses

1. Use a co-generator (“warmtekrachtkoppeling”)

Greenhouse CO₂ generators do exist and are used in greenhouses. A cogenerator (also known as: combined heat and power (CHP) (in Dutch: “warmtekrachtkoppeling” (WKK)) in a greenhouse produces CO₂ as a by-product through the combustion of fuel, such as natural gas or biomass, to generate electricity.

The exhaust gases containing CO₂ are strategically released into the greenhouse environment, enhancing photosynthesis and promoting accelerated plant growth.

2. Use industrial CO₂

Another way to obtain CO₂ in greenhouses is to get CO₂ from nearby industrial facilities, where CO₂ is captured and supplied as a by-product of industrial processes. In the Netherlands, there is a pipeline transporting CO₂ from the Rotterdam harbour to the greenhouses located in Westland.

3. use Liquid CO₂ in tanks

Another way to supply CO₂ in the greenhouses is with external CO₂ tanks. Liquid CO₂ is transported to greenhouses in specialized tanks. This source of CO₂ is then released into the greenhouse atmosphere to support photosynthesis. This source of CO₂ could be relatively expensive to use.

Indoor agriculture in 2024 – Data Driven Growing in Smart Greenhouses

Data-driven growing in greenhouses improves the quality of the final yield, sustainability of the operation and labour efficiency.

Growing crops commercially indoors is more expensive than outdoor production. Making use of data can help a grower to make wiser and better short-term and long-term choices.

By embracing the latest technologies in agriculture that also records production data in greenhouses, growers are better protected from future challenges.

Smart greenhouses can be considered as technologically advanced agricultural facilities that make use of automation, precision agriculture, and controlled environment techniques.

This could be in either mid-tech or high-tech greenhouse facilities.

A smart greenhouse makes use of sensors and data analytics to optimize factors like temperature, humidity, and nutrient levels, creating an efficient crop growth environment.

Energy-efficient technologies, automation, and in the future, the utilization of machine learning during harvesting contribute to a reduced reliance on manual labour, which is challenging to find in many places around the world.

The integration of IoT in smart greenhouses enables real-time monitoring and data-driven decision-making for increased productivity and resource management in the greenhouse.

Many of these technologies and automation methods are already being used in Dutch greenhouses.

What type of Greenhouse Climate Control Computers exist?

There are different types of greenhouse climate control computers available on the market. The choice of the best greenhouse computer system depends on the size of the greenhouse and how modern the greenhouse is—the level of technologies implemented in the greenhouse.

All climate computers receive data from sensors to measure the prevailing greenhouse conditions. A more advanced version of the greenhouse computer also measures different plant parameters and uses optimization models and weather predictions to create a better growing environment for greenhouse crops while reducing the usage of energy.

For a small, low-tech greenhouse, a simple greenhouse controller to turn on/off the lights or to switch on/off the heating might not be enough.

However, this type of controller has limited abilities to efficiently control humidity or to increase energy efficiency in the greenhouse.

Switching from low-tech greenhouses to mid-tech greenhouses with the use of greenhouse climate control systems can professionalize and optimalize the greenhouse operation.

11 Advantages of Operating a Climate Controlled Greenhouse

Creating a uniform climate in the greenhouse helps increase the quality of the crops and contributes to reducing pest and disease occurrences.

Curious about other advantages of having a climate-controlled greenhouse through an automated greenhouse system?

Below, we have listed the things that Dutch greenhouse climate control systems can do to optimize yield and increase profitability.

The specific features of the greenhouse climate control system depend on the type of system you have purchased for your greenhouse.

1) Precision environmental control in automated greenhouse:

Achieve precise control over temperature, humidity, light levels, CO₂ concentration, energy screens, and the opening of roof windows for optimal plant growth.

The greenhouse control system makes decisions on environmental control in the greenhouse based on the preset conditions and outdoor weather conditions.

2) Making use of real-time data:

Greenhouse sensors throughout the compartments will gather real-time data on environmental conditions, ensuring accurate and immediate control adjustments. The crops will receive the exact amount of resources based on what they truly need. This reduces the use of resources such as nutrients and energy (for heating and cooling).

3) Automated greenhouse ventilation optimization:

The greenhouse ventilation system can automatically adjust based on the plants’ current needs and the prevailing weather conditions, which optimizes the airflow within the greenhouse.

4) Efficient greenhouse irrigation management:

Based on sensor data, the greenhouse system or the grower can adjust the irrigation in the greenhouse, ensuring optimal water levels at the right moment, promoting efficient and healthy plant growth.

5) Precision fertilization strategies:

The greenhouse climate computer can implement precise fertilization strategies, allowing for tailored nutrient application based on plant requirements. This promotes optimal growth while minimizing resource wastage.

6) Energy efficiency strategies:

Implement crop growth algorithms and research-based strategies to optimize energy usage for heating, cooling, and lighting, contributing to energy efficiency and reduction of operational costs.

Dutch greenhouses aim to be climate neutral in 2040 and reducing the usage of fossil fuels and other energy sources are essential to achieve that target.

7) Data analysis for informed decisions & future decision-making:

The greenhouse environment control system gathers important data throughout the day and analyses historical data to make better decisions with machine learning in the future.

Not all greenhouse climate control systems provide this option. Search for advanced greenhouse climate control systems to find the suitable climate computer based on your needs.

8) Thorough greenhouse insights and recommendations:

Similar to above, advanced smart greenhouse climate control systems can provide insights and recommendations (both short term and long term) to growers based on data analysis to optimize cultivation practices and enhance overall efficiency.

9) Wireless Communication:

Smart greenhouse climate control systems support wireless communication for connectivity between sensors throughout the greenhouse complex, sensors from the weather station outside of the greenhouse, actuators (fans, misting system etc), and the central control system.

This is important, as it ensures efficient data collection throughout the whole greenhouse. Also, it facilitates data exchange between the sensors and the greenhouse climate control system.

10) Remote monitoring and cloud-based solutions – saving every data point:

Because all the data is collected automatically and the growing system as well, growers can monitor and adjust settings remotely through a user-friendly interface. Data are automatically saved on cloud-based platforms for analysis and accessibility (meaning that the greenhouse data are saved and can not be lost).

Even when the grower is not present in the greenhouse, the person still can operate the greenhouse from a distance. With this feature of the greenhouse climate control system, a greenhouse production consultant can be hired from abroad that can control and give well-informed advice from a distance.

11) Alarms for quick intervention:

When the system measures an abnormal climate or irrigation value that has surpassed the pre-set deviation, a real alarm will be activated and/or a message will be sent to all connected devices. In this way, fast interventions can be taken by the grower to re-adjust the crucial growing factors such as the pH, EC and temperature.

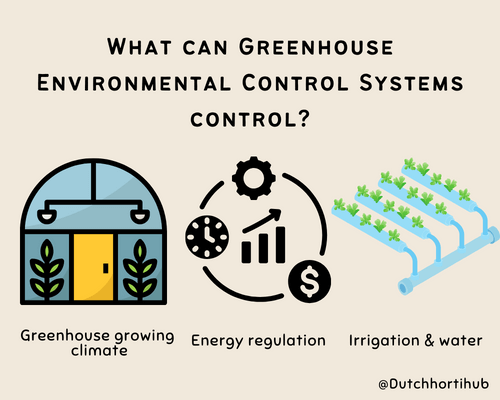

What can Greenhouse Environmental Control Systems control?

You might wonder: what can a climate computer control? Depending on the level of advancement of the greenhouse climate control computer, the below-mentioned elements can be regulated.

The more elements the greenhouse climate control system can regulate in the greenhouse, the more automated the greenhouse becomes.

Since climate control in greenhouses is a crucial factor for productivity, it is wise to consult with the company providing the greenhouse environmental control system to determine which one would be the most suitable for your greenhouse.

The decision is also based on the amount of compartments the greenhouse has.

Greenhouse growing climate

- Greenhouse temperature control (heating elements)

- Crop temperature control (sensing leaf temperature)

- Greenhouse humidity control (misting, evaporative pads)

- Greenhouse ventilation control (fans)

- Air treatment per compartment

Energy regulation in greenhouse

- Boiler for heat and heat management

- Heat pump

- Heat buffer

- Heat exchanger

- Outdoor Aquifer

- Management of total energy usage

Water

- Water silos

- Hydroponic water system (pH, EC)

- Disinfection of reused nutrient water

- Pretreatment of water

- Irrigation valves

Separated irrigation control computers

Besides climate control computers, separate irrigation control computers also exist. They can work independently or in combination with climate control computers. With an irrigation control computer, the right nutrient recipe for each crop can be provided. Additionally, the pH of the hydroponic nutrient solution and the EC level of the irrigation water can be regulated.

Case study – Autonomous Greenhouse Challenge: the future of growing with Greenhouse Climate Computers

To showcase what the future of greenhouse control looks like with making use of data, plant growing models, and artificial intelligence (AI) we want to share some insights of the Autonomous Greenhouse Challenge, a challenge organised by Wageningen University & Research (WUR) in the Netherlands.

This challenge is unique as it fosters the collaboration of AI engineers and computer sciences students to work closely together with horticulturists/plant scientists.

Since the first edition of the Autonomous Greenhouse Challenge, which happened in 2018, three editions have taken place.

The goal of the autonomous greenhouse challenge is to determine how greenhouse growers around the world could use technology to increase plant production, quality, and profit without entering the greenhouse

During each of the challenges, Wageningen University & Research provided the plants, greenhouse, data platform, standard sensors, and cameras.

The selected teams, that went through a competitive online hackathon, needed to develop the machine learning and computer vision algorithms to grow the crops remotely and autonomously.

The team that can maximize the net profit the most (by controlling the greenhouse climate and crop with AI techniques) and could produce in the most sustainable way, while having a good AI strategy, wins the challenge.

The past winners of this challenge outperformed the yield of experienced Dutch growers, while reducing the usage of energy.

The Autonomous Greenhouse challenge shows that integrating prediction models in a greenhouse climate computer will allow growers to produce more in a smarter way.

In 2024, Dutch and international teams consisting of scientists, professionals, and students will again participate in the fourth edition of the greenhouse challenge.

Growing greenhouse crops based on Plant Empowerment – “Het Nieuwe Telen”

The Dutch horticulture sector has the ambition to be climate neutral in 2040, through a combination of reducing and making energy consumption more sustainable.

Plant Empowerment will be the new way of growing crops in Dutch greenhouses. It is concept developed in the Netherlands, which is also known as “Het Nieuwe Telen”.

The literal translation of this word in English would be “the new way of growing”. Plant Empowerment as growing strategy uses insights of plant physiology and focusses on the actions and decision making in the greenhouse around the plants.

When a balance of growth factors are found, crops will perform well. Strategically focussing on how to create an optimal growing condition for the crops, results in better performing crops and higher yields, while the usage of energy in greenhouses can be reduced.

Dutch Greenhouse Climate control computers

Dutch expertise in greenhouse technology has positioned Dutch climate control computers as industry leaders, providing a sustainable and resource-efficient solution for the greenhouse horticulture sector.

Dutch Greenhouse Climate control computers play a crucial role in optimizing environmental conditions for efficient plant growth in greenhouses around the world.

Using Dutch greenhouse climate control systems can help you improve the growing environment and increase your yield.